You may have seen “SKU” codes on products and delivery documents, but what does SKU stand for and how are retailers using them?

SKU stands for Stock Keeping Unit.

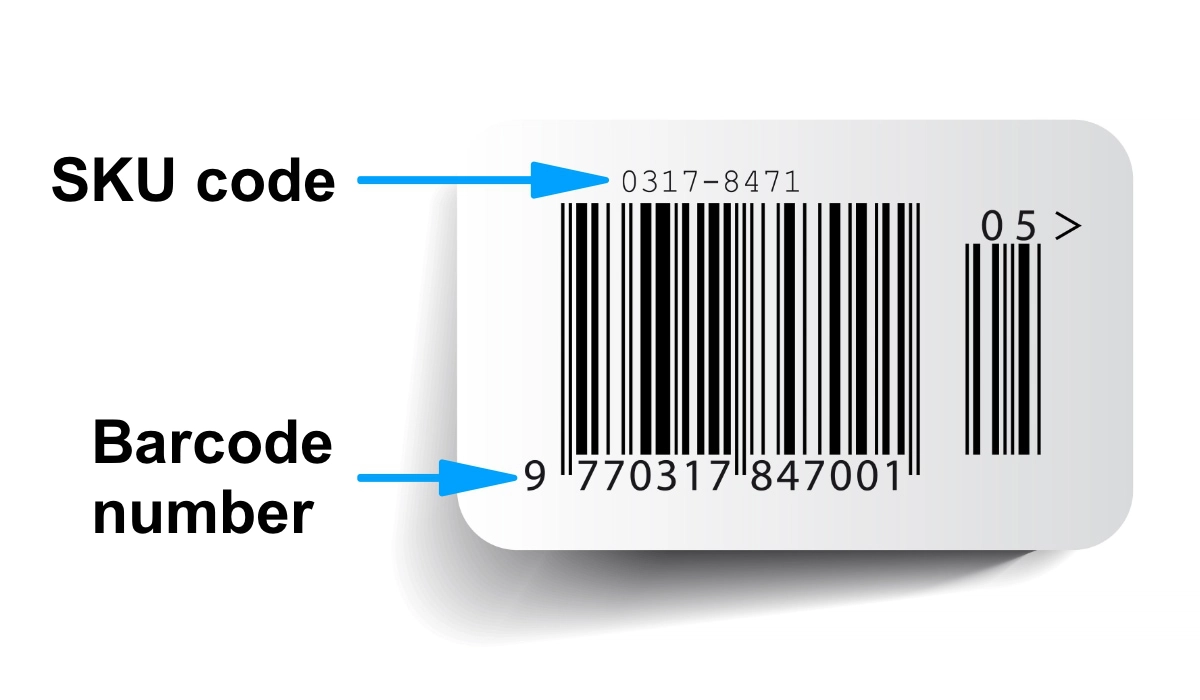

It is an 8- to 12-character code consisting of numbers and letters with unique product trait information attached to it. Sometimes, they are called product codes or part numbers.

Retailers assign SKU numbers themselves to the variants of products they sell in order to differentiate between stock of specific items.

A SKU code can contain information about:

- Manufacturer

- Variants (e.g. colour, size, type)

- Other information useful for your shop

Once it is registered in your point of sale (POS) or ecommerce system, you’ll be able to check it in the system to identify stock levels across locations, incoming deliveries and other item details.

It is different from a barcode number (below barcode) and UPC (“universal product code” consisting of 12 numbers) that contain information applicable across different retailers. UPCs and barcodes are assigned by the GS1 organisation so they apply internationally.

In contrast, SKU codes are unique to the retailer, so the same code is meaningless for other retailers. Businesses do not have to use them, but many do for their practical advantages, as we shall now cover.

Practical applications in retail

The main purpose of SKU numbers is to manage stock accurately, both in store and in ecommerce. Specifically, they enable you to:

- Check and adjust stock levels

- Record losses

- Analyse item sales

- Track the location of items

- Coordinate supply orders

You may want to check your stock availability from the EPOS/inventory system, before digging through the stock room or delivery boxes to find a particular item while a customer is waiting.

And you’ll definitely want to time purchase orders to avoid an “out of stock” situation. As your product selection and sales volume increase, so does the complexity of reordering. You’ll need to coordinate replenishment to avoid an excess of unpopular items that won’t sell and shortage of popular items that tend to sell out.

Some POS systems automate ordering from suppliers. A retailer can then set a minimum item count that triggers a reorder, and a maximum level for how many you want in store. And referencing products with their SKU codes makes it more likely you’ll get exactly the items you need.

Last but not least, ecommerce stores benefit too. Product recommendations in an online store can be based on SKUs, and stock availability of product variants is reliably updated when they are correctly recorded.

See also: 50 features to consider in a POS system

How SKUs address stock issues

While SKU codes can track items and help automate purchase orders, they need to be registered correctly too, in order to avoid:

Although different, they are symptomatic of similar things. When you’ve got negative stock, it typically means you haven’t registered incoming stock from a delivery correctly, and subsequently sold those items. (By the way, not all POS software can show negative stock, so check this with your EPOS provider)

Sometimes, negative stock is a result of a mistake where the person receiving a delivery has registered goods as something else, resulting in phantom stock. To solve this, you correct the negative stock (to zero or positive number) and count the products it could’ve been mistaken for. Once you identify the phantom stock, you correct that in the system too.

Product codes help you check stock in your inventory system.

Phantom stock could also mean theft. If you can’t find the items you’re supposed to have, they might be stolen. If that’s the case, you may want to change your display to protect the items prone to theft, or train staff to be more vigilant in store.

In these ways, discrepancies between actual and registered stock levels can actually help you pinpoint issues in the shop and address them.

How SKUs are created

To take advantage of SKU codes, they need to be added in your POS and inventory system.

This doesn’t have to be complicated when you use an automatic SKU generator, sometimes included in the till software or ecommerce platform. If it isn’t, there are free tools online like Zoho SKU Generator and Katana where you can create and download SKUs to a spreadsheet uploadable in your inventory system.

Alternatively, you can manually decide on the SKUs and add them one-by-one if the product library isn’t too big. There are no universal requirements for its composition, but here’s a typical pattern that many SKU systems follow:

- First 2-3 characters: Product category, department or supplier

- Next few characters: Product attribute #1

- Next few characters: Product attribute #2

- Last characters: Product-identifying number

The last ‘identifying number’ ensures that products sharing the same characteristics in the first part can have a unique, sequential number to differentiate them.

Based on this, you could create the following code:

Category: Paper = PA

Brand: Epson = EP

Type: High-gloss = HG

Sequence identifier = 04= SKU: PAEPHG04

The most important thing about SKU structure is to be consistent with its logic, so it’s easier to understand them without checking. Knowing, for example, that “01” at the end means the colour black means you might not need to look up its meaning while handling stock.

Once the SKUs are attached to their corresponding items in the inventory library, they will be associated with all the details of that item’s profile including the barcode (if you have added a barcode to the profile).